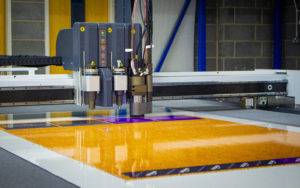

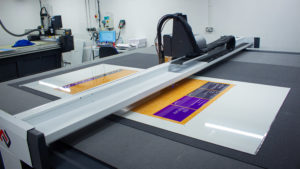

Banner Box has strengthened its production capabilities with the purchase of a brand-new JWEI JCUT 3230 cutting machine, bringing the company’s total to four cutters. As part of this upgrade, all cutting operations have now been relocated into a dedicated area positioned directly alongside the print room. This strategic move is designed to enhance workflow, reduce turnaround times, and deliver even greater consistency across our full range of printed products.

For customers, the benefits are immediate, particularly for those ordering rigid print. With cutting and printing now operating side by side, materials move through production faster and with improved precision, ensuring cleaner edges, tighter tolerances, and an overall higher-quality finish.

“Investing in new technology is about giving our customers the very best,” said Director Ryan Shelton. “By centralising our cutting operations and adding additional capacity, we’re streamlining our processes and further improving the quality, speed, and reliability our customers expect from Banner Box.”

This investment marks another step forward in Banner Box’s commitment to continuous improvement, enabling the team to handle higher volumes, offer more flexibility, and maintain exceptional standards across every job.